This chapter covers

- What continuous flow is and why you want it

- Eliminating waste to achieve flow

- Managing flow with kanban

- Using daily standups to help the work flow

- Choosing what to work on next

- Managing bottlenecks using the Theory of Constraints

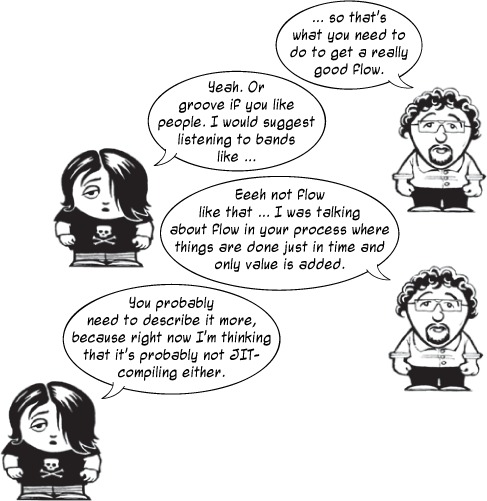

Flow, or rather one-piece continuous flow, has been the cornerstone in Toyota’s[1] production vision for decades. A one-piece continuous flow is a system in which each part of work that creates value for the customer moves from one value-adding step in the process directly to the next, and so on until it reaches the customer, without any waiting time or batching between those steps. Instead of building up inventories just in case, things are produced only when needed, just in time—at the right place and in the right quantity: no more, no less.

1 Toyota is the company that pioneered the Toyota Production System (TPS), which Lean is based on.

This continuous flow turns every process into a tightly linked chain in which everything is connected. There is nowhere for a problem to hide, no inventory of other work or products to work on if something stops or breaks; so when things break, you immediately know what’s happened, and you’re forced to solve the problem together. It forces people to think, and through this they become better team members and people.